We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

Let's face it: large-scale construction projects have many moving pieces and can prove to be challenging at times.

The ticking clock of tight deadlines and the puzzle of translating complex designs into reality is enough to challenge even the most seasoned pros.

These situations are all too common in the construction industry, but here's the good news: there's a solution that can address these issues and help you build better, faster, and more sustainably. That solution is precast concrete.

Grab a cup of coffee, because we're diving into seven common construction challenges and showing you how precast concrete can be the solution you've been searching for.

Every construction project comes with a schedule, and that schedule often feels ambitious.

The usual issues like delayed deliveries, surprise storms, or labour shortages are common, and they have a way of impacting project timelines.

You know the feeling. We've all been there. You're carefully reviewing that project timeline, adjusting resources and strategizing to stay on track.

And you're not alone in this. McKinsey tells us that large-scale projects typically take 20% longer than planned. Another study by KPMG found that only 25% of projects come within 10% of their original deadlines.

With precast concrete, your floor slabs and walls show up on time, every time.

Built in a climate-controlled factory (where even the weather is on your side!), precast components sidestep those unforeseen delays that usually impact job sites. Rain or shine, your project keeps cruising along.

Precast's predictable timelines take the guesswork out of scheduling. And if life happens and you need to adjust that delivery date, we’ve got plenty of storage space around here, so your precast pieces stay safe and sound.

The phone rings. It's another call from a subcontractor, and it's not good news – they’re short-staffed.

Unfortunately, in the construction world, finding and keeping skilled workers is becoming more challenging.

Tasks take longer and your project timeline shifts. When you're working hard to finish with a smaller crew, quality can be affected.

Worse, less experience on the job can mean more safety concerns.

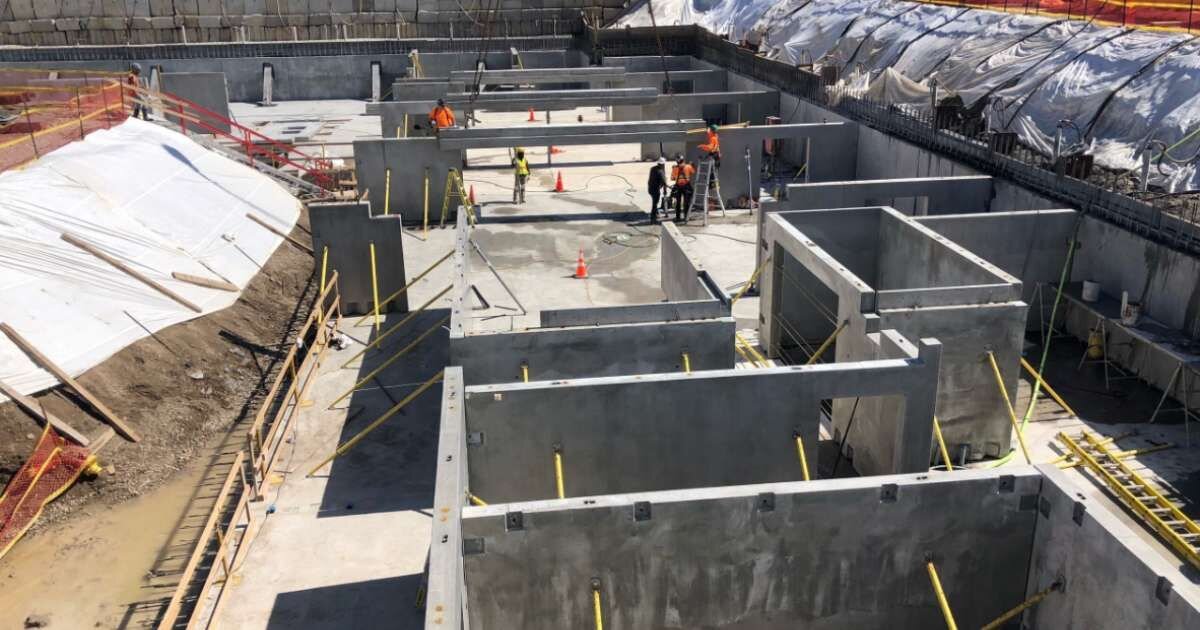

Picture this: a tractor-trailer pulls up to your site, not just with a load of concrete, but with your precast walls ready to become part of your building. A small team of crane operating pros swoops in and makes those walls part of your structure faster than you can say "efficiency."

That's the magic of precast.

Precast products arrive partially or fully finished, which means less work for your crew on-site. By letting the precast manufacturer handle most of the heavy lifting (literally), you streamline your project, maintain top-notch quality, and create a safer environment for everyone.

Ever seen an architect's drawings and wondered, "How are we going to bring this to life?"

Fancy curves, detailed finishes, and complex geometries can look amazing on paper, but translating them into reality on-site is often more involved.

Turning complex shapes from 2D blueprints into 3D structures is a puzzle that doesn't always fit together perfectly. Sometimes, the architect's vision might present challenges for traditional building materials. What seems totally feasible in a cozy studio might require careful consideration on the construction site.

With precast concrete, your custom-designed elements roll up to your site, ready to fit seamlessly into your project like a Lego masterpiece.

Using custom-built forms, precast manufacturers can precisely replicate even the most intricate designs with a level of precision only possible in a controlled factory environment.

Precast concrete transforms that complex design puzzle into a smooth, satisfying process.

In construction, safety is the name of the game. Keeping a site safe is a 24/7 responsibility. There are the daily safety briefings, the endless paperwork, and the hope that your efforts are enough to keep everything running smoothly.

Think about it: the more work that's done off-site, the fewer workers are exposed to the complexities of a construction site. That's another advantage of precast.

Manufactured in a controlled factory setting, precast components significantly reduce the amount of work that needs to be done on-site.

By moving a big chunk of the construction process to this safer, more predictable setting, precast lets you sleep a little better at night.

Construction sites aren't always the most eco-friendly. The dumpster bins, the muddy terrain, and the constant road of earth-moving engines can prompt you to reflect on the environmental impact of your project. Especially knowing that the construction industry is responsible for a lot of air and water pollution, as well as landfill waste.

You want to do the right thing, but it's a balancing act between building fast and cost-effectively, and being sustainable.

Precast offers a more sustainable way to build. It starts with being smart about materials, using only what's needed and minimizing waste during production.

But the eco-benefits don't stop there. Precast structures are built to last, so they need less upkeep and won't need replacing as often. It's like buying a high-quality pair of boots – sure, they cost a bit more upfront, but they'll save you money (and landfill space) in the long run.

Less maintenance means fewer resources used over time – it's a win-win for your project and the environment

Sometimes, a project’s budget can go off course. Unexpected expenses arise suddenly, turning your budget meetings into focused discussions on "Where can we spend less?" It's a juggling act between keeping costs down and quality up.

These aren't just numbers on a spreadsheet, they're the heart of project management decisions. They can lead to delays, disagreements, and in extreme cases, significantly impact the project.

With precast concrete, you get upfront, transparent pricing – no surprises, no hidden fees, no stress. You know exactly what you're spending, making it way easier to manage your resources and avoid those dreaded cost overruns that keep you up at night.

Precast concrete transforms budget management from a challenge into a breeze. It's a solution that lets you focus on building your project, not reviewing your spreadsheet.

Ever feel like you're playing a real-life game of Tetris on your construction site? Limited space is a common challenge, especially in urban areas or projects with tight footprints. When you're constantly juggling material deliveries, equipment maneuvering, and worker movement, it's easy for things to get crowded.

These logistical complexities can have real consequences. A congested site slows everything down and can pose more safety concerns.

With precast, your components arrive just when you need them. No need for massive storage areas filled with materials.

Your precast pieces are ready to be installed right off the truck, freeing up precious space and making your site less cluttered.

Tight timelines, labour shortages, complex designs, safety concerns, environmental impact, budget constraints, and limited site space can all add up to a challenge for even the most seasoned construction professional.

But it doesn't have to be that way.

For construction and project managers, precast concrete is more than just a building material, although it is an incredible one. It's also a strategic tool that can streamline your projects, ease pressure, and improve your bottom line.

If you're ready to explore new solutions, it's time to consider precast concrete for your next project. Contact a Fritz-Alder Precast today to learn more about how precast can help you build better, faster, and more sustainably.